Horizontal Emulsifier

5000.00 - 15000.00 INR/Set

Product Details:

X

Horizontal Emulsifier Price And Quantity

- 1 Set

- 5000.00 - 15000.00 INR/Set

Horizontal Emulsifier Trade Information

- 50 Set Per Year

- 50 Days

Product Description

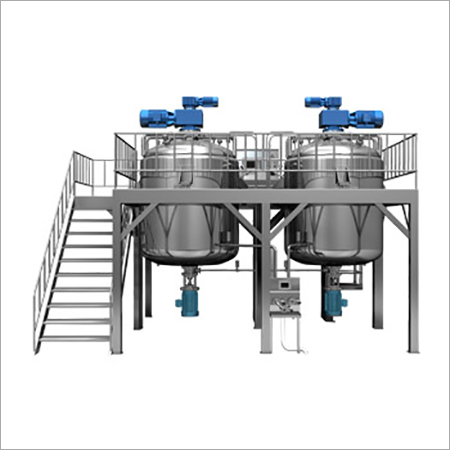

TZZRJ Horizontal Emulsifier

Horizontal Emulsifier is an extremely effective machine, which is demanded for high shear applications. It can provide speedy hydraulic and mechanical shear. This is an inline as well as separate freestanding machine that ensures cost effectiveness and functional efficiency. It is relevant for the industries of food, chemical, medicine, adhesives and others. It can be used with countless substances such as beverages, food colors, syrups, medical ointment, toothpaste, lotions, milk, creams, shampoos, detergents, vitamins, hair dye, adhesives and other ingredients. Horizontal Emulsifier is a high quality industrial mixer as well as sole method of blending, which ensures accuracy and speed. This enables a complete shearing mixing action and can mix both dry as well as powdered ingredients.

Summarize:

The TZZRJ Series vacuum mixing emulsifier is an improved version of the vacuum mixing emulsifier based on the imported German technology. This equipment finds its usage in cosmetic and ointment product industry. It comprises an emulsified tank, water tank, oil tank, vacuum and hydraulic systems as well as an electric controller. The features for which this equipment is highly recommended amongst the industries are as follows:

- Easy operation and stable performance

- Compact structure and convenient cleaning and maintenance

- Good homogenization effect

- High production benefit

- Automatic control

Technical Features:

- SUS316L stainless steel is used for contact parts, and mirror polished inside and outside of the equipment.

- Automatic control of all pipelines and parameters. The electric appliances are from Siemens, Schneider and so on.

- There is a CIP cleaning system with emulsifying tank for easy and effective cleaning.

- Tertiary agitating system is adopted by emulsifying tank, and maintains a vacuum conditioned through the process of emulsification. It completely eliminates the generation of spume in the emulsification processing and prevents unnecessary pollution.

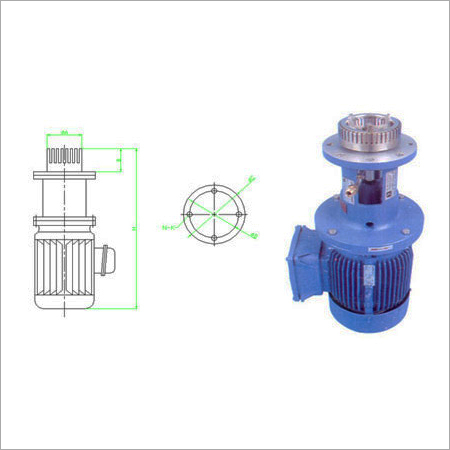

- Based on an advanced technology, homogenizer can get a suitable emulsifying effect. The high emulsification speed is 0-3500r/min, and the low mixing speed is 0-65r/min.

Safeguard:

- When emulsifying tank discharges the material, the elevating gear cannot work in order to avoid the bump between the stirring device and the emulsifying tank.

- The emulsifying tank could not overture when the cover hasnt risen to the peak in order to avoid the bump between the stirring device and the emulsifying tank.

- The body and the upper cover of the emulsifying tank should be with security lock catch when the material is discharging under positive pressure.

- At meantime the elevating gear could not work .

- When the vacuum system is startup, there will be negative pressure in the emulsifying tank, so the elevating gear could not work.

- when the upper cover of the emulsfiying tank has risen, the stirring device could not work in order to injure the operator.

Our equipment improvement and innovation:

- The control panel adopts seamless rolling technology and without any slit , it is easy to clean.

- The low speed agitator using the helical gear can withstand torque and prolong the operational life due to the unique design and the high accuracy processing. The noise is only 20 decibels even at the highest speed.

- It uses latest mixing axes, which is convenient to disassemble. One just has to remove the screw in order to replace the damaged part. PTFE is used as a sealing material. It is also according to the international pharmaceutical and foodstuff standard.

- The high speed emulsification device works on the method of adjustment balance calibration of mobile and stable to ensure good emulsified effect and prolong the operational life.

- A unique temperature transmitter is used as the fluidity and the thermal conductivity of paste are different from liquid. The material temperature can be quickly transmitted to temperature controller device during the material processing and the temperature error is1.

- An energy conservation pipeline is used when machine electrically heated, so it can prevent thermal from divulging and heat promptly. There is a pressure safety device in this equipment that can mediate pressure automatically in case of overpressure. There is a glass sight with all the jackets that makes it easy to observe the liquid position.

Tertiary Agitating System

The low speed agitating device comprises the outside frame type agitator and the middle oar type agitator. The frame-type agitator's periphery is with the scraper, it can scrape off the material which cohere on the vessel's inside wall. There is an impeller and a stator in this high speed emulsifying device. During high speed revolving processing, the material indraft from impeller's upper and lower part, then ejects from the slit of the impeller and the stator. T the time of indrafting and ejecting process,the material after complex physics reaction like intense extrusion, mixing and injecting, so the material gets a complete emulsification. Triplicate agitating system comprises the high speed emulsifying device and the low speed agitating device, it can enable the mixing, homogenizing,emulsifying of material with viscosity of 5000cp in a short time.

Main Technical Parameter:

| (Model) | (Cubage) | (Emulsify) | (Agitator) | (Outside dimension) | |||||

| Kw | r/min | Kw | r/min | (L) | (W) | (H) | (MH) | ||

| TZZRJ-30 | 30L | 1.5 | 0-3500 | 0.75 | 0-70 | 1500 | 800 | 1500 | 2050 |

| TZZRJ-50 | 50L | 3 | 0-3500 | 0.75 | 0-70 | 2750 | 2100 | 1900 | 2600 |

| TZZRJ-100 | 100L | 3 | 0-3500 | 1.5 | 0-70 | 2800 | 2150 | 2100 | 2800 |

| TZZRJ-150 | 150L | 4 | 0-3500 | 1.5 | 0-70 | 2850 | 2150 | 2150 | 2900 |

| TZZRJ-200 | 200L | 4 | 0-3500 | 1.5 | 0-70 | 3000 | 2200 | 2200 | 3100 |

| TZZRJ-350 | 350L | 5.5 | 0-3500 | 2.2 | 0-70 | 3650 | 2650 | 2550 | 3600 |

| TZZRJ-500 | 500L | 7.5 | 0-3500 | 2.2 | 0-50 | 3800 | 2800 | 2700 | 3950 |

| TZZRJ-750 | 750L | 11 | 0-3500 | 3.7 | 0-50 | 3900 | 3900 | 2900 | 4400 |

| TZZRJ-1000 | 1000L | 11 | 0-3500 | 3.7 | 0-50 | 3900 | 3400 | 3150 | 4550 |

| TZZRJ-2000 | 2000L | 22 | 0-3500 | 7.5 | 0-50 | 4850 | 4300 | 3600 | |

Enter Buying Requirement Details

Other Products in 'Vacuum Emulsify And Fill Equipment' category

|

Ruian Global Machinery Co Ltd

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese