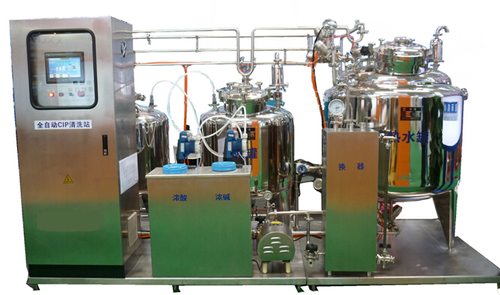

Infusion Mixing Tank

Product Details:

Infusion Mixing Tank Price And Quantity

- 1 Set

- 10000.00 - 50000.00 USD ($)/Set

Infusion Mixing Tank Trade Information

- shanghai

- 10 Set Per Year

- 45 Week

- wooden box

- GMP

Product Description

PYG injection mixing tank

Application:

It applied to infusion, injection, eye drop, oral liquid, blood preparation, biology, fine chemical and fermentation industries.

Structure:

- This injection tank include tank, mixer, pipes, pH meters,valves, temperature control system, heating system, cooling system and control system.

- The detail requirement should be according to customer requirement.

Description:

This infusion tank can be used pharmaceutical, biology industry, fermentation eye drop industry, different types of blades and relevant speed achieve the production condition. This mixing tank can be used with combination of flow meter, liquid level indicator, temperature sensor etc. functional accessories. Main shaft seal types: stuffing seal, mechanical seal, and magnetic seal. Jacket can be used to achieve heating preservation, cooling, heating etc

Parameter:

| Model | 30L | 50L | 100L | 200L | 500L | 1000L | 2000L | 3000L | 5000L | 10000L | 50000L |

| Diameter mm | 300 | 300 | 400 | 500 | 700 | 900 | 1200 | 1300 | 1500 | 1800 | 3100 |

| Height mm | 1600 | 1700 | 2000 | 2300 | 2600 | 3000 | 3800 | 4300 | 4500 | 5300 | 8000 |

| Filling capacity | 65%-80% | ||||||||||

| Inside Pressure Mpa | -0.1---5 | ||||||||||

| Jacket pressure Mpa | 0.1---5 | ||||||||||

| Cool method | By jacket | By pipe | |||||||||

| Mix speed rpm | 0--300 | ||||||||||

| Motor Power kw | 0.55 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 13 | 55 |

Feature:

- Material adopts SS316L or 304, inside surface roughness is Ra0.28-0.4m, outside surface roughness is Ra0.4-0.6m.

- Impeller form: Propeller, anchor

- Jacket form: Dimple jacket, full jacket or coil jacket.

- Insulation material adopts rock wool, polyurethane or pearl cotton.

- Components: Vent filter, sight glass, pressure gauge, manhole, cleaning ball, wheel, thermometer, liquid level gauge, and control system or according to clients specific requirement, such as load cell or other special requirement

Specification: 30L-200000L

- top agitator: mechanical agitator, 10-71rpm

- Zero hold up aseptic design of bottom outlet valve

- Calibrated full view glass for the blending vessel

- CIP and SIP style design of vessel, fittings and piping

- Injection ports, injection needles available on the top of the lid

- Volume monitoring by load cells

- Process Automation

Order requirement:

- How much liter of mixing tank do you need?

- what this tank used for?

- What way do you want to heat the mixing tank ? By steam or electric?

- How much speed of the mixer do you need? Do you need Frequency speed?

- When do you need this mixing tank?

Other Products in 'Injection equipment' category

|

Ruian Global Machinery Co Ltd

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese