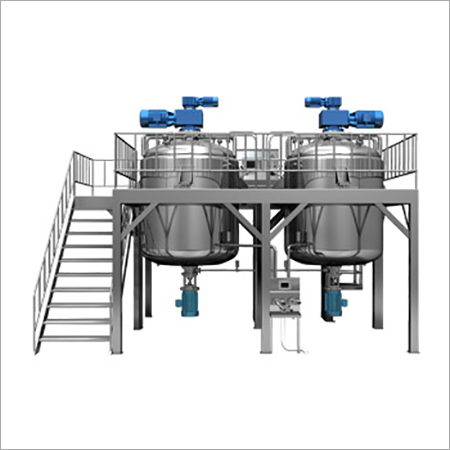

Bottom Homogenize Mixing Tank

5000 INR/Set

Product Details:

X

Bottom Homogenize Mixing Tank Price And Quantity

- 1 Set

- 5000 INR/Set

- 5000.00 - 15000.00 INR/Set

Bottom Homogenize Mixing Tank Trade Information

- Shanghai, China

- 50 Set Per Year

- 50 Days

- Wooden Case

- CE, ISO, GOST

Product Description

TZZRJ Bottom Homogenize Mixing Tank

Application:

- Cosmetic and daily chemical product: Cosmetic cream, lotion, shampoo, detergent, health care product, gel, Laundry detergent, hand sanitizer, armpits lotion etc.

- Pharmaceutical product: Ointment, Ice packs, injection liquid, penicillin etc.

- Food : Salad, mayonnaise, peanut butter, sesame butter, buttery, Animal fat, iced products, healthy food etc.

- Beverage: Fruit Juice, Milk Juice etc.

- Chemical: Paints, Pigments, dyes, photo solvents, Rubber and resin, pesticides ,Shoe polish, general chemicals etc.

Structure:

- This homogenize tank include tank, homogenizer, vacuum pump, water tank, mixer, pipes, meters, valves, temperature control system, heating system, cooling system and control system.

- The detail requirement should be according to customer' requirement

Description:

This stainless steel homogenize tank is used for mixing, dispersing, dissolving, emulsification, dissolution, reaction, formulating, heating, cooling, warm-keeping, cultivating, disinfecting and storage etc. Different types of blades and relevant speed achieve the production condition.

Feature:

- Suit for the process about formulating, dissolving, heating, cooling, warm-keeping, cultivating, disinfecting and storage. It is available online CIP cleaning (only suitable for enclosed structure)

- Designed in accordance with sanitary requirements, so the structural design is very user-friendly, easy to operate, healthy to store.

- The inner surface is mirror-polished (roughness Ra0.4m); the welding of all kinds of nozzles, endoscopic, manholes and the pot adopt stretch flanging process

- arc transition, easy to clean with no dead ends, ensure the reliability and stability in the production process.

- The main blending adopts stepless speed variation device, which can reduce the formation of bubbles when the temperature is low and the viscosity is high.

- The gear pump circulating discharging device can accelerate the forming of products and realize rapid discharging

Main Technical Parameter

| (Model) | Cubage | (Emulsify) | (Agitator) | (Outside dimension) | |||||

| Kw | r/min | Kw | r/min | (L) | (W) | (H) | (MH) | ||

| TZZRJ-30 | 30L | 1.5 | 0-3500 | 0.75 | 0-70 | 1500 | 800 | 1500 | 2050 |

| TZZRJ-50 | 50L | 3 | 0-3500 | 0.75 | 0-70 | 2750 | 2100 | 1900 | 2600 |

| TZZRJ-100 | 100L | 3 | 0-3500 | 1.5 | 0-70 | 2800 | 2150 | 2100 | 2800 |

| TZZRJ-150 | 150L | 4 | 0-3500 | 1.5 | 0-70 | 2850 | 2150 | 2150 | 2900 |

| TZZRJ-200 | 200L | 4 | 0-3500 | 1.5 | 0-70 | 3000 | 2200 | 2200 | 3100 |

| TZZRJ-350 | 350L | 5.5 | 0-3500 | 2.2 | 0-70 | 3650 | 2650 | 2550 | 3600 |

| TZZRJ-500 | 500L | 7.5 | 0-3500 | 2.2 | 0-50 | 3800 | 2800 | 2700 | 3950 |

| TZZRJ-750 | 750L | 11 | 0-3500 | 3.7 | 0-50 | 3900 | 3900 | 2900 | 4400 |

| TZZRJ-1000 | 1000L | 11 | 0-3500 | 3.7 | 0-50 | 3900 | 3400 | 3150 | 4550 |

| TZZRJ-2000 | 2000L | 22 | 0-3500 | 7.5 | 0-50 | 4850 | 4300 | 3600 |

|

Enter Buying Requirement Details

Other Products in 'Vacuum Emulsify And Fill Equipment' category

|

Ruian Global Machinery Co Ltd

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese